Are you tired of feeling overwhelmed by the complexities of managing your WordPress site? Do you find yourself wishing for a simpler and more effective way to make your website stand out? You’re not alone. Many WordPress users struggle to navigate the myriad of tools and options available, often feeling lost in the process.

But fear not! We’ve got you covered. In this guide, we’ll introduce you to five essential tools that will not only simplify the management of your WordPress site but also optimize its performance for maximum impact, especially in today’s world of AI. Say goodbye to confusion and hello to a streamlined and successful website!

What you can expect from this guide:

- How to automate SEO writing using OpenAI GPT call WP GPT Poster

- How to ensure your WordPress is SEO Friendly using the Yoast SEO plugin

- How to market and improve your website SEO

- How to Engage with your Audience and grow them

- How to create a great graphics using Canva

Now that you know what to expect from this guide and are armed with the knowledge of the tools we’re going to explore, it’s time to embark on your journey to WordPress greatness.

Let’s begin by exploring each of these essential tools in detail, starting with the ultimate content creation companion:

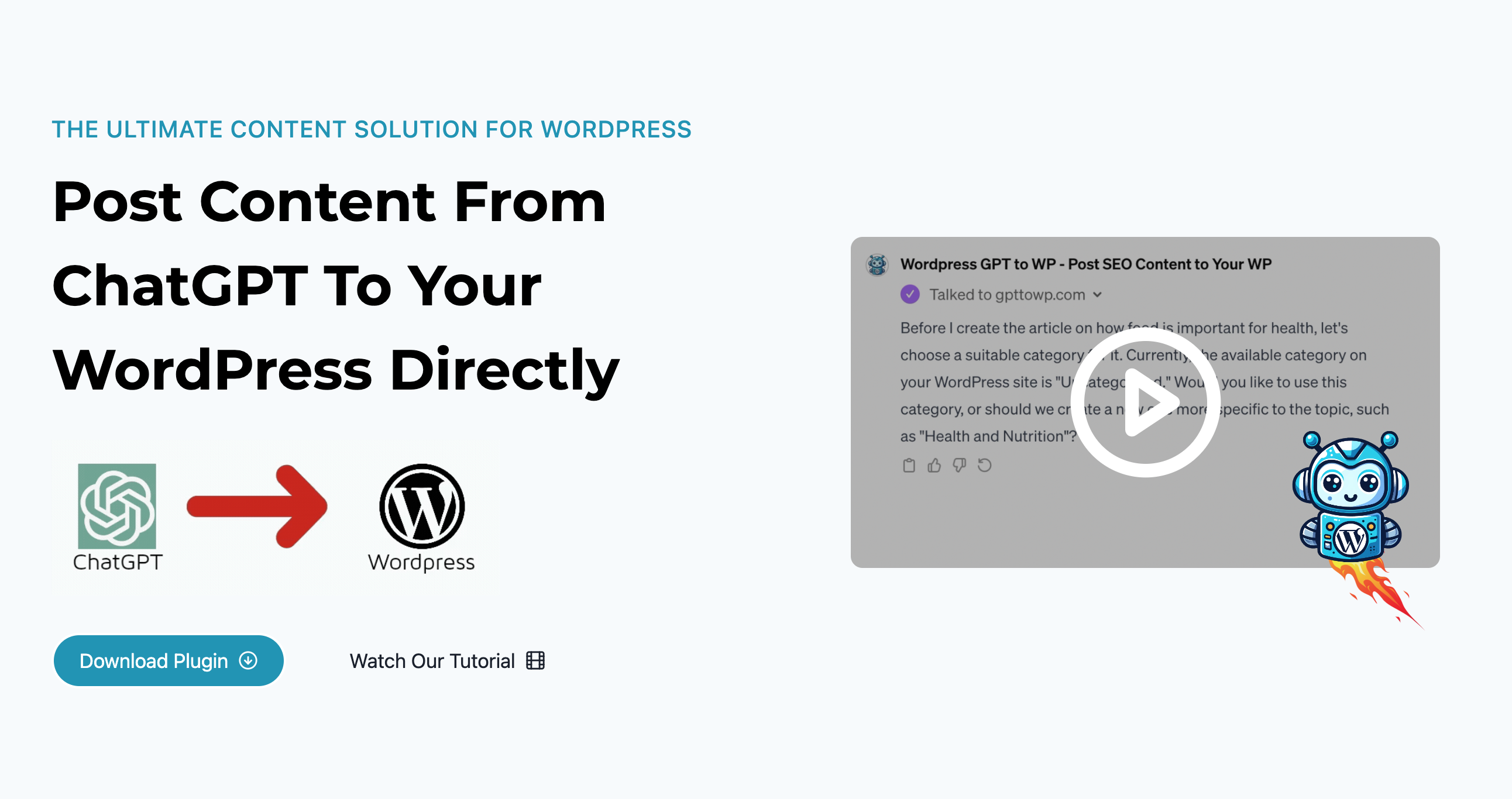

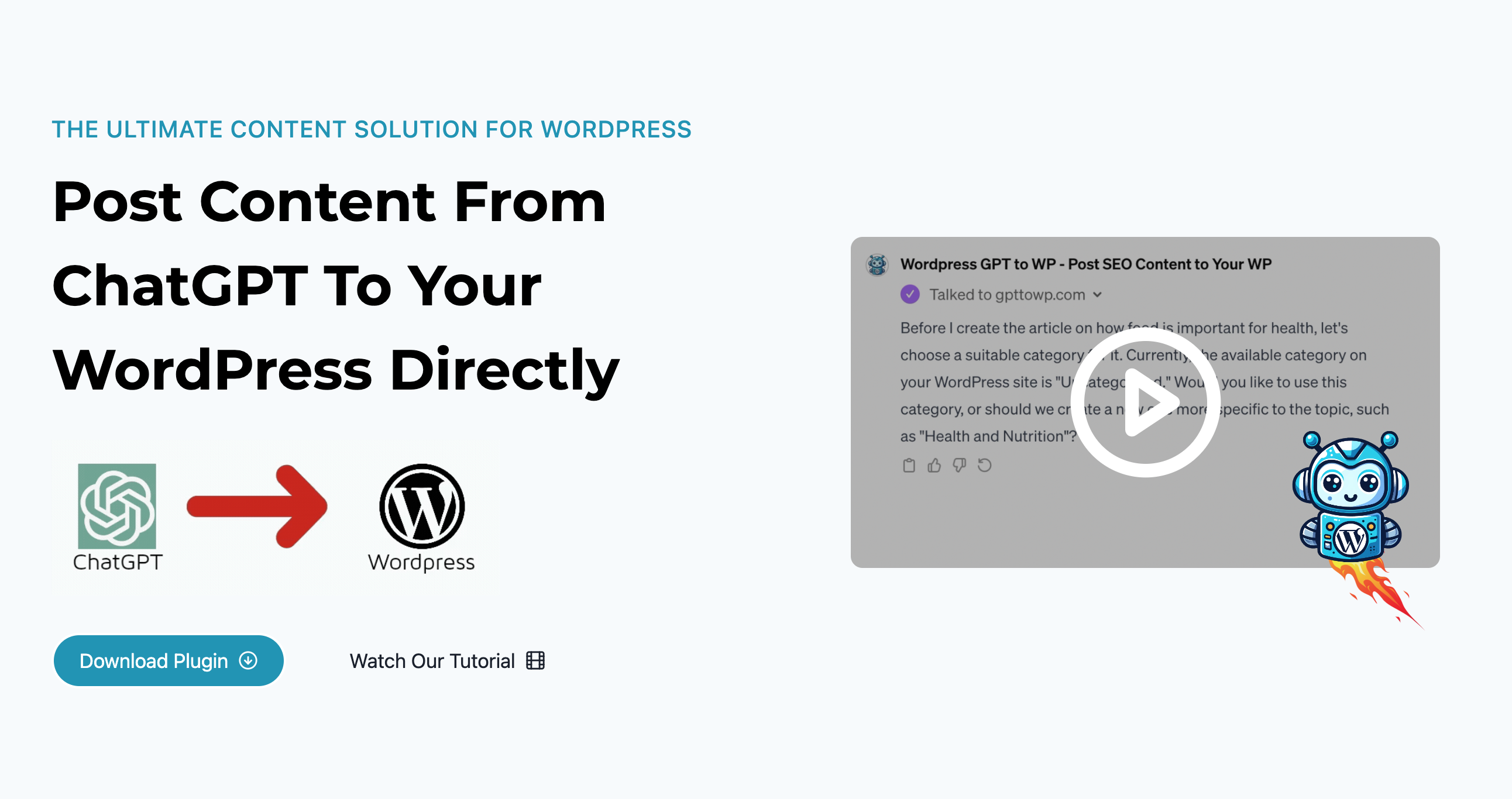

1. WP GPT Poster: Your Ultimate Content Creation Companion

Introducing WP GPT Poster, your ultimate content creation companion! Are you tired of spending hours brainstorming ideas and crafting articles for your WordPress site? With this GPT, you can kiss writer’s block goodbye. This revolutionary tool harnesses the power of OpenAI’s GPT interface to help you effortlessly generate high-quality articles, complete with SEO-optimized tags, categories, and featured images and post it directly to your WordPress.

Imagine having an AI-powered assistant at your fingertips, ready to assist you in creating engaging content for your audience. With GPT to WP, you can bring your ideas to life in a fraction of the time, leaving you with more energy to focus on growing your website and engaging with your audience.

2. Yoast SEO: Streamline Your Optimization Strategy

Now that you have amazing content ready to go, it’s time to ensure it gets the attention it deserves. Enter Yoast SEO, the ultimate tool for streamlining your optimization strategy. Say goodbye to the complexities of SEO and hello to simplified optimization.

With Yoast SEO, you can easily optimize your content for search engines, making it more discoverable to your target audience. From analyzing keyword density to providing real-time suggestions for improvement, Yoast SEO takes the guesswork out of SEO, helping you achieve higher rankings and increased visibility effortlessly.

3. Backlinkforce: Boost Your Site’s Authority with Ease

Building authority for your WordPress site is essential for standing out in a crowded online space. With Backlinkforce, you can supercharge your site’s authority effortlessly. Say goodbye to the tedious process of acquiring backlinks and hello to a streamlined solution.

Backlinkforce specializes in acquiring quality backlinks that boost your site’s credibility and visibility. By leveraging the power of Backlinkforce, you can increase your site’s authority and attract more traffic, all without breaking a sweat.

4. Mailchimp: Engage Your Audience Like Never Before

Engaging your audience is key to building a successful WordPress site. With Mailchimp, you can take your audience engagement to new heights. Say goodbye to the hassle of managing email campaigns and hello to a more efficient solution.

Mailchimp allows you to easily collect visitor information and send customized email campaigns, newsletters, and promotions. From personalized content to automated workflows, Mailchimp helps you stay connected with your audience and drive engagement effortlessly.

5. Canva: Elevate Your Visuals with Stunning Graphics

Last but not least, let’s talk about visuals. With Canva, you can elevate your website’s visual appeal with stunning graphics. Say goodbye to boring stock images and hello to professional-quality visuals that captivate your audience.

Canva provides a vast library of templates and tools to help you create eye-catching graphics for your WordPress site. From blog post images to social media graphics, Canva has everything you need to make your site stand out from the crowd.

Bringing It All Together: Your Path to WordPress Greatness

Now that you know about these essential tools, it’s time to put them into action. Follow these steps to simplify and supercharge your WordPress site:

- Use GPT to WP to Create Amazing Content: Let GPT to WP assist you in generating high-quality content effortlessly.

- Optimize Your Content with Yoast SEO: Streamline your optimization strategy to improve your site’s visibility.

- Boost Your Authority with Backlinkforce: Supercharge your site’s authority with quality backlinks.

- Engage Your Audience with Mailchimp: Stay connected with your audience and drive engagement effortlessly.

- Enhance Your Visuals with Canva: Elevate your site’s visual appeal with stunning graphics.

By incorporating these tools into your WordPress site, you’ll be well on your way to WordPress greatness. Say goodbye to the complexities and hello to a simpler, more powerful website management experience. Try them out today and watch your business grow!

Careers2 years ago

Careers2 years ago

General2 years ago

General2 years ago

Travel2 years ago

Travel2 years ago

Culture2 years ago

Culture2 years ago

Careers2 years ago

Careers2 years ago

Entertainment2 years ago

Entertainment2 years ago

Entertainment2 years ago

Entertainment2 years ago

Travel2 years ago

Travel2 years ago